Phone

Toll Free

HEAVY EQUIPMENT TIPS FOR SAFETY AND LONGEVITY

Heavy equipment like the kind found in most industrial or machine-based businesses should be treated with respect at all times. Heavy equipment can be dangerous to operate and expensive to repair if something goes wrong.

You should always make sure that all of your employees follow proper protocol when interacting with heavy equipment to increase your equipment's lifespan and also maintain a safe work environment. You should also keep these other heavy equipment tips for safety and longevity in mind.

Check Your Equipment Before and After Every Job

If your employees don't use an inspection checklist before they begin work and after they close up shop, you need to correct this oversight immediately. Close and careful inspection of your heavy equipment before you put it into operation could help you detect any potential safety or maintenance problems.

Create a culture focused on maintaining these daily inspections and you'll likely be able to fix any potential issues before they escalate. If something doesn't look quite right, it's possible the situation could quickly escalate once the equipment is turned on.

Check Up on Your Employees to Make Sure They Are Using the Right Tools

Does your heavy machinery use attachments to adapt to specific situations? If you need a specific plough or bucket for a specific situation, make sure your employees are using the right tool for the job.

Trying to force the wrong attachment or tool onto a piece of heavy machinery could be a recipe for disaster. The attachment could fall off or go flying while in operation and cause a safety hazard or damage to the main piece of machinery.

Check That You Have the Right Safety Gear

When you double check that your employees are using the right attachment or tool for the job, also be sure to inspect the actual employee and make sure they are equipped with the right safety gear. Keep your warehouse or work site well-stocked with everything you need so no employee has an excuse to go without the proper gear.

Eye protection, hand protection, and sturdy non-slip work boots should be the bare minimum expected of all employees. You can add to this list based on your own needs, such as a hard hat for an outdoor construction site.

Check That the Work Area Is Free of Hazards

You can make inspecting the surrounding work area a key part of your daily pre-work inspections, but it's also important to make sure that the work area remains clear throughout the rest of the day. The moment anyone notices a potential trip or slip hazard, all nearby equipment should be shut down until the area is cleared of all hazards.

Check That Your Employees Are Communicating Frequently

It can be hard to hear while heavy equipment is in operation. It can be helpful to arm your entire team with a set of walkie talkies that can be used to communicate across the work site.

If the machinery is so loud that even that won't work, come up with a system of hand signals that can be used to communicate. For example, an employee who needs to pass through a specific work area could use a hand signal to let the operators know that they will be nearby.

One bad mistake while operating heavy equipment could cause significant damage to your property or the equipment itself. A careless act could also end up putting your employees in harm's way.

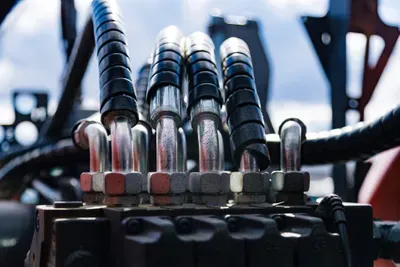

At Carolina Hose & Hydraulics, we have years of experience servicing and repairing heavy equipment just like yours.

Contact us today to schedule a regular inspection of your equipment or to start a repair. Our seasoned professionals can help keep your equipment running safely and smoothly for years to come.

Phone: 864-576-1452 | Toll Free: 800-476-1495 | Email: office@carolinahose.com

Address: 208 Northeast Drive Spartanburg, SC 29303

Serving Spartanburg, SC, Greenville, SC, Columbia, SC, Augusta, GA

Business Hours:

- Mon - Fri

- -

- Sat - Sun

- Closed