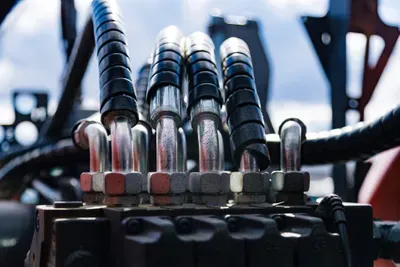

CONTAMINATION AND YOUR HYDRAULIC SYSTEM

Hydraulic pumps provide the power necessary to operate many types of industrial machinery. A hydraulic pump that doesn't properly can spell disaster for your company.

Contamination is one of the most common causes of hydraulic pump failure. A basic understanding of the types of contamination that can plague your hydraulic pump is essential. This knowledge allows you to recognize evidence of contamination and invest in repairs before your pump sustains permanent damage.

Built-In Contamination

Contamination within your hydraulic pump occurs at the time of manufacturing. Each of the mechanisms and parts that make up a hydraulic pump are machined individually before the manufacturer assembles them.

Built-in contamination occurs when burrs or chips left behind after machining break loose. Loose burrs and chips then travel through your hydraulic pump, causing scoring on interior pump walls or damaging delicate pump seals.

A high-quality filtration system attached to your hydraulic pump will easily prevent damage from built-in contamination. The small burrs and chips that break loose filter out of your pump's hydraulic fluid before any permanent damage can occur.

Ingressed Contamination

Regular oil changes keep your hydraulic pump functioning properly. Unfortunately, oil changes can also become a source of potential contamination.

If the new oil that you add to your pump already has contamination with dirt, water, or debris particles, these contaminants will eventually find their way into your hydraulic pump.

Ingressed contamination will damage internal seals and cause scoring on the rods and motors within your hydraulic pump. Scoring has the potential to limit the efficiency of your pump, leading to premature pump failure. Damaged or loose seals allow dirt and moisture to infiltrate your hydraulic pump.

Only experienced technicians capable of eliminating exposure to outside contaminants should be allowed to complete oil changes or replace damaged seals within your hydraulic system if you want to avoid the negative effects of ingressed contamination.

Aeration Contamination

Air and your hydraulic system do not mix. Whenever air becomes trapped within the hydraulic hoses and components that power your equipment, aeration occurs. This type of contamination can have catastrophic consequences on your hydraulic machinery's performance.

Aeration affects the seals in your hydraulic system by causing them to dry out and crack. Damaged seals contribute to hydraulic fluid leaks, which cause your machinery to lose power. Aeration also affects the pistons in your hydraulic system. Aeration causes the piston heads to become rounded and the pump to easily damage.

Routine visual inspections are useful in preventing aeration contamination. An experienced repair technician can identify any connections within the hydraulic system that may allow air to enter during a visual inspection.

If a professional adds a grease lubricant around these connections at regular intervals, this can prevent air getting into the hydraulic system through loose or damaged inlet connections.

Moisture Contamination

Not just air can wreak havoc on your hydraulic system. Moisture can as well. Industrial hydraulic machinery operating in a humid work environment is prone to moisture contamination.

Moisture alters the viscosity level of the oil within your hydraulic system. A higher or lower oil viscosity will lead to cavitation or premature pump failure. The easiest way to avoid moisture contamination is to check the breathers on your machinery regularly.

The breathers will pull any moisture in the outside environment into the hydraulic system. Routine visual inspections of these components let you catch moisture problems before they interfere with oil viscosity.

Contamination could spell disaster for your hydraulic system. You must be vigilant in watching for evidence of built-in contamination, ingressed contamination, aeration contamination, or moisture contamination when maintaining your hydraulic equipment.

Contact Carolina Hose & Hydraulics for more information on contamination and its effect on your hydraulic systems.