AVOID INDUSTRIAL GEARBOX PROBLEMS WITH PERIODIC MAINTENANCE

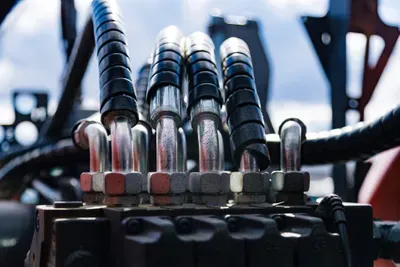

With advances in technology, the transmission systems in heavy equipment have improved to meet the demands of modern industrial applications. Today's transmission systems are smoother, more efficient, and easier to troubleshoot. However, these systems and their components still require periodic servicing.

A gearbox is an important component of any industrial machine's transmission system. Primarily, the gearbox regulates the machine's speed and increases torque. These two processes are particularly central in heavy industrial equipment where the gear's reliability and lifespan are important.

Considering the importance of gears in the operation of heavy machinery, neglecting the gearbox can lead to low production rates, equipment breakdown, and costly downtimes.

Here are some common problems that can result from lack of proper industrial gearbox maintenance.

Improper Lubrication

Lubrication is important for the optimal performance of a gearbox. Heavy machine owners or operators should carefully select the right type of lubrication for industrial machines.

Consider factors such as the lubricant's viscosity, chemical composition, and the density of the oil film. All these factors will affect the lubricant's ability to prevent metal-to-metal contact between bearings and gears.

The lubricant should be sufficiently viscous to coat the surface of the gear teeth easily. Bear in mind that different types of gearboxes require a certain level of lubricant and a specific method for lubricating the gears and bearings.

Lastly, contaminated lubrication can minimize the lifespan of the gear and other related components. Be sure to check and change lubricant oil as recommended by the equipment manufacturer.

Bearing Failure

Several factors can cause gear bearing to fail. These include overloading the gearbox beyond capacity, normal wear and tear, corrosion, contamination, and overheating, among other factors.

Bearing failure or bearing fatigue can change the internal clearance of the gearbox, therefore diminishing the efficiency of the gearbox and the machine's transmission system as a whole.

Internal clearance refers to the maximum distance through which a mechanical system such as a gear can move. When the clearance is too small, the gears may be unable to move properly to regulate speed and maximize torque.

Alignment Issues

Ideally, gears should interact seamlessly with the transmission's axle shaft. For optimal performance, the gear teeth should also have sufficient clearance. When this design arrangement is compromised, misalignment of the gearbox, bearings, and other components of the transmission system may occur.

Factors that may cause the gearbox to misalign include using the wrong gearbox, which can lead to overloading and bending of the gearbox. Alignment issues may also result from improper gearbox installation, distortion from excessive heat, and worn bearings.

Misalignment can minimize the gear's lifespan and, eventually, result in complete gear damage. Regular equipment maintenance can help to identify the early signs of gearbox misalignment and mitigate complete failure.

Overheating

Industrial applications are intense and gearboxes are therefore prone to overheat, which can diminish the gearbox's efficiency and lifespan.

Oil leakages, inadequate lubrication, and contaminated lubricant can also contribute to gearbox overheating. Other possible causes of overheating include gearbox misalignment, clearance issues, and misaligned couplings.

Heavy machine owners can prevent overheating through periodic evaluation and servicing of the gearbox.

The operation of industrial equipment and machinery depends on a gear system that works properly. A solid gearbox can increase production rates, improve the life expectancy of machinery, ensure safety, and minimize the life-cycle costs. Periodic maintenance performed by a reputable technician can help you get the most out of your industrial gear systems.

At

Carolina Hose & Hydraulics , we have the right tools and expertise to assemble new units as well as rebuild most types of gear systems. Get in touch with us today to find out more about our products and services.