HAS YOUR HYDRAULIC SYSTEM FAILED? 4 PROBABLE CAUSES

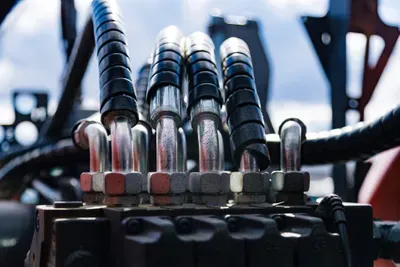

Hydraulic systems are essential in many applications. From hydraulic lifts, brake systems, weight lifters and loaders, pumps, and steering systems to heavy equipment, the systems leverage hydraulic energy to deliver mechanical energy. When every component in the hydraulic system performs optimally, your equipment delivers the power you need for the job.

Any breakdown in one part of the system leads to low power output and can cause further system damage. If you notice signs such as slow operation, abnormal noise, or high temperatures, call a hydraulics specialist to check the system.

Below are some of the most common causes of hydraulic systems' failure you should know.

1. Overheating

Every hydraulic system has the optimal temperature level where you get maximum power output. When a component in the system fails, you can experience higher-than-normal temperatures, which are a warning sign of underlying issues.

When hydraulic fluid temperatures rise above 180°F, the oil degrades faster and the system risks more damage. Fluid oxidization, thinning, and thickening all occur when the hydraulic system overheats.

The fluid problems reduce the efficiency of your hydraulic equipment. To prevent such situations, ensure the heat dissipation from your system exceeds the heat load from the equipment's operations.

2. Air and Water Contamination

Air and water contamination can lead to hydraulic system failure. When air enters the system, the hydraulic system suffers aeration or cavitation. You might notice unusual noises due to air contamination, and the equipment is at a higher risk of failure.

Air in the system also affects lubrication and can also increase the temperatures, which degrades the fluids in your hydraulic system. Cavitation causes knocking noises in your equipment, increased wear of the components, and contamination of the fluid, which increases the risk of system failure.

Water contamination is another major cause of hydraulic trouble. If you notice the fluid has turned milky, have a professional inspect the system to diagnose if water contamination is the cause. Water entry into your equipment can corrode the hydraulic pump and other internal components. Such parts often require costly replacement and also reduce the life of your hydraulic system.

3. Fluid Issues

Hydraulic fluid is critical for the operation of any hydraulic equipment. The fluid provides energy transmission through the system, which makes your equipment operate seamlessly. Whenever you have an issue with the hydraulic fluid, the entire system suffers.

Fluid contamination reduces the expected output from your equipment. Other fluid issues can arise because of poor-quality oil or products incompatible with the type of coils you have in your equipment. When you buy hydraulic fluid, look for high-resistance fluid that can withstand temperature-related problems.

Another hydraulic fluid issue to look out for is a low fluid level from a leak somewhere in the system. When the level drops significantly, you'll notice performance issues or a gurgling sound from the power unit. With internal leakage, you can expect excessive temperatures that lead to further system problems.

4. Human Factors

Human factors can cause a wide range of hydraulic system issues. If you have a hydraulic system, take proactive care to identify any warning signs of failure early.

Poor maintenance, use of incompatible components, and faulty installation of components can lead to risky situations, costly damage, and low output. When a hydraulic unit is inefficient, your organization spends more money on energy, which reduces your bottom line.

Hydraulic systems are invaluable in applications that require reliable power. The systems are easy to control, deliver high power levels, and are affordable to maintain. However, you can only enjoy the benefits if you maintain the system in optimal shape by avoiding the common causes of hydraulic failure highlighted here.

For all your hydraulic systems care and maintenance in Spartanburg, SC, our team at Carolina Hose & Hydraulics is ready to help. Since 1978, we have delivered outstanding hydraulics solutions to clients in the area and beyond. Contact us today, and enjoy exceptional hydraulics services from our team.