SMALL PARTS OF A HYDRAULIC SYSTEM AND HOW TO CARE FOR THEM

From car transmissions and brakes to lifts and factory equipment, the things a hydraulic system can power are truly versatile. Thanks to hydraulic technology, we can use liquids to more effectively energize numerous systems.

However, just because the mechanic capabilities of liquids are amazing doesn’t mean that maintaining these systems is effortless. In fact, you can’t even limit your focus to just the most obvious equipment.

A hydraulic system is composed of many small components, all of which work together to keep the equipment running smoothly. While many of these parts are small and inexpensive, if you don’t maintain them appropriately, their state of disrepair can lead to bigger, more expensive problems. Here are some small components to pay attention to.

Pistons

One of the more famous parts of hydraulic systems, pistons are small cylinders that apply appropriate pressure so that the system functions.

Pistons move within cylindrical tubes, building pressure and causing fluids such as oil to move throughout the system. Hydraulic systems work because the force that pistons put on the system’s incompressible fluid — oil — causes pressure to build and force to be magnified so the system has the power it needs.

To make sure that the piston works as effectively as possible, make sure you use clean oil and change the oil according to the instructions of your equipment’s manufacturer. If the oil you use becomes too dirty, then the oil won’t provide the same degree of pressure and will corrode your machinery.

Piston Rings

For pistons to work, they need to be sufficiently free of wear and corrosion. One component used with the piston, the piston ring, is especially important to watch because it holds the cylinder components in place and helps make sure the pressure in the system is contained.

While pistons tend to be made of lighter metals, the piston ring is usually more durable and made of a material like cast iron. Still, don’t take the ring’s longevity for granted. Watch the piston ring to make sure it is in good shape. Replace the ring when necessary so that you don’t run into bigger problems.

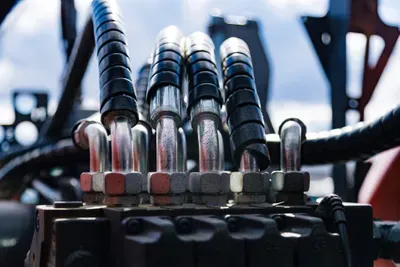

Pins, Joints and Rods

Hydraulic cylinders have various small components that may seem insignificant but in fact are essential to the integrity of your hydraulic system. For example, rods need to be straight so that they can smoothly connect various pieces without puncturing seals. Pins tie the various cylinder components together so they can work in harmony.

The same goes for ball joints and other small parts. If your joints are too worn or are bent so that they don’t have the appropriate angles, then the alignment of your system will be off. If the components of a hydraulic system are not properly aligned, then they won’t work as efficiently as they can, and eventually bigger parts may break.

Seals

High-quality seals maintain the position of rods and other pieces, help the system maintain the appropriate pressure levels, and keep undesirable liquids or air from entering and causing corrosion.

If you have a punctured or torn seal, your hydraulic system will not work as efficiently as it can, and it may stop working altogether. Pressure and the movement of fluid are the things that make hydraulic systems effective, and seals are essential to both of these powers.

If a small part of your hydraulic system needs repair, take care of the issue right away. When you take care of the small components, they help you take care of the large, expensive pieces. By maintaining your system, you can keep your hydraulic system working as well as possible and for as long as possible.

If you need new equipment or want some help with equipment maintenance, just contact

Carolina Hose & Hydraulics, Inc. We’ll be happy to help you find the machinery you need and take care of it for you so you can work as efficiently as possible.