SECURE YOUR FUTURE BY PROTECTING YOUR INVESTMENTS — MAINTAINING HEAVY EQUIPMENT

No matter how the global economy evolves over the years, the construction industry will remain a vital part of growth and development. If you own a construction company, it's essential that you take steps to make sure you're not shut out of that growth, and instead can fully benefit from your potential.

Finding yourself stuck with antiquated or damaged equipment is one way to find yourself struggling to keep up with your competition. If you don't commit to solid maintenance practices that shield your investment in your equipment, you might struggle to establish a foothold in the marketplace.

Below, you'll find a guide to some steps you can take to maintain your heavy equipment. Following these suggestions can guarantee that your business ownership remains profitable and responsible and can put you in a position to bid for exciting and innovative projects. You'll also be able to enjoy a much greater return on your equipment investments, allowing you to take more steps toward success.

Thorough Cleaning

One part of proper machine maintenance that tends to be forgotten is properly training employees. If someone is going to be operating a heavy piece of equipment, it’s important that they know all of the rules and regulations that go along with it.

Be sure that new employees are well aware of how to handle equipment. Additionally, old employees should be re-trained on equipment procedures to make sure the information stays fresh in their mind—after all, everyone occasionally needs a reminder to stay out of bad habits. Even if you’re used to using a certain piece of machinery or equipment, mistakes happen. Frequent training is a great way to avoid these kinds of problems.

Clear Guidelines and Rules

It can be difficult to stay on top of all of the oversight responsibilities that come with a construction site. Most people who operate a construction business have a skill for the creation and get a lot of joy out of seeing structures arise from their hard work, but taking the time to slow down, pump the brakes, and carefully contemplate their next step may have less appeal.

Even if it's not an exciting process, regular inspections are essential for equipment ownership. As mentioned above, early warning signs can be incredibly valuable in preventing serious issues from developing.

Before you send a piece of equipment out to a job site, make sure to have it checked over by an experienced professional who will be sensitive to those warning signs and can help you respond as quickly and thoroughly as possible.

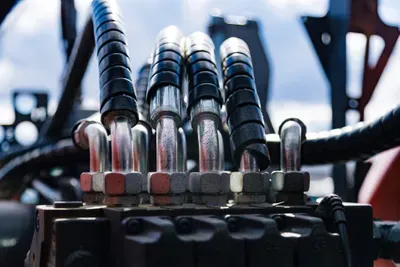

Consistent Lubrication

Heat, friction, and other strong forces can be enemies of your equipment, even under optimal usage conditions. Construction equipment is designed to be rugged, but after a while, even the toughest equipment needs to be greased to avoid metal-on-metal damage that can quickly become a serious problem.

Maintaining a regular lubrication regimen is an important step in guaranteeing your equipment can avoid untimely breakdowns. Make sure you consult with the equipment manufacturer when choosing oil and grease, as the use of improper products can end up causing more damage than the right lubricants can avoid.

The professionals at Carolina Hose and Hydraulics are prepared to handle

all of your heavy equipment service needs. Trusting reliable professionals to help maintain your equipment can allow you to focus on the tasks that you're best at and can help guarantee that your equipment will always be able to serve you when it's needed.