HEAVY EQUIPMENT STORAGE AND HUMIDITY LEVELS

Heavy equipment needs an appropriate storage space, whether the equipment is used daily or seasonally. One of the more insidious factors in equipment deterioration is humidity. Because the level of humidity in a room or outdoor area can change quickly and unexpectedly, controlling for humidity can be a frustrating endeavor if you don't have a fully climate-controlled warehouse.

You can beat the humidity, though, by being aware of how it works and compensating for potential changes. Don't forget to also have the equipment inspected on a regular schedule to ensure that small problems don't balloon into big disasters.

Dry Can Be Just as Damaging

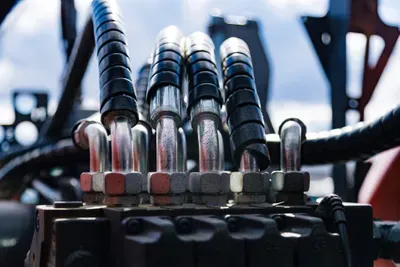

First, overly humid conditions are not the only ones you need to watch out for. Super-dry conditions in which the humidity is very low, such as can occasionally strike in winter, can make hoses, gaskets and other rubber parts on the equipment dry out and crack.

This is not as big a problem in the Carolinas and the Southeast as it can be in other regions, like Texas and the Southwest, but it is something to watch out for should record-low humidity occur.

If low humidity occurs and the equipment is in an enclosed storage building like a warehouse, adding a humidifier will help. Check with the manufacturer of the equipment regarding optimal humidity ranges.

If the equipment is outside, you can try covering it or moving it to a sheltered area where walls and tarps create a more humid microclimate that is protected from the wind.

Fluctuating Levels Bring Their Own Problems

Do not assume that low humidity one day and high the next means everything will even out. The equipment may still suffer from cracked rubber and problems with condensation. If the weather is such that you're experiencing a see-saw effect at the storage site, create a shelter and install humidifiers and dehumidifiers as needed.

Dead Spaces Need Remediation

One issue that all storage spaces can develop is dead space, those still spaces where there isn't a lot of ventilation or airflow. Even if the rest of the area has a reasonably good humidity level, these dead spaces can create extra-humid conditions. Position equipment so that there are no blocked zones, and install and use fans in these areas if you can't avoid creating them.

Ambient Temperatures Contribute to the Problem

Remember that the temperature also helps create condensation. Sometimes it's not a matter of controlling the humidity but rather controlling the temperature. On cold nights, for example, an unheated room that is not totally cold can result in a lot of condensation. Adding a heater to raise the room's temperature can eliminate that problem.

Do look for heaters meant for storage areas that can be left alone. Your average home space heater is too much of a fire risk to leave on while you leave the storage area.

Preparation for Anything Is Best

If you're going to store heavy equipment, it's best to create a storage area where you can compensate for most environmental phenomena. Take a cue from climate-controlled storage units, which have decent insulation, protection from exterior weather phenomena and mild heating and air conditioning that keep the storage space just warm or cool enough to fend off condensation and overheating.

If you must store the items outside and you hit a very humid patch of weather, try to dry the equipment as best you can.

As you work on your storage area, have the equipment inspected, and repaired if needed, by

Carolina Hose & Hydraulics, Inc. Finding and fixing issues caused by exposure to too much or too little humidity needs to be done early on so problems are not left to fester.